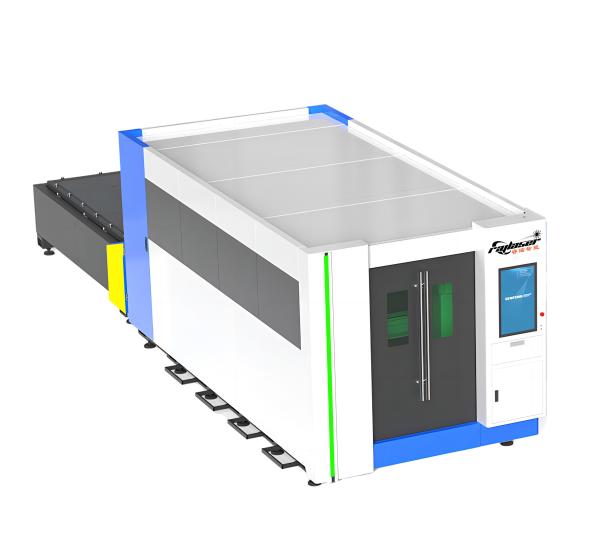

| Categories | Enclosed Laser Cutting Machine |

|---|---|

| Place of Origin: | China |

| Brand Name: | RayLaser |

| Price: | Negotiation |

| Certification: | CE |

| MOQ: | 1 |

| Packaging Details: | Wooden |

| Delivery Time: | 7-30days |

| Payment Terms: | T/T |

| Supply Ability: | Sets/M |

| Application: | LASER CUTTING |

| Applicable Material: | Metal |

| Condition: | New |

| Laser Type: | Fiber Laser |

| Cutting Area: | 1500mm*3000mm |

| Cutting Speed: | 0~100m/min |

| Graphic Format Supported: | AI, PLT, DXF, BMP, Dst, Dwg, LAS, DXP |

| Cutting Thickness: | 0~30mm |

| CNC or Not: | Yes |

| Cooling Mode: | WATER COOLING |

| Control Software: | CYPCUT |

| Laser Source Brand: | MAX Raycus |

| Laser Head Brand: | Raytools |

| Servo Motor Brand: | Yaskawa |

| Guiderail Brand: | HIWIN |

| Control System Brand: | Cypcut |

| Weight (KG): | 3500 KG |

| Key Selling Points: | High Productivity Low Maintenance |

| Optical Lens Brand: | Wavelength |

| Warranty: | 3 years |

| Applicable Industries: | Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Farms, Construction works , Energy & Mining, Other, Advertising Company |

| Machinery Test Report: | Provided |

| Video outgoing-inspection: | Provided |

| Warranty of core components: | 3 years |

| Core Components: | Pressure vessel, Motor, Gear, Gearbox, Engine, PLC |

| Mode of Operation: | continuous wave |

| Configuration: | gantry type |

| Products handled: | Sheet Metal |

| Feature: | Programmable Servo Motor |

| Performance: | High Performance |

| Speed: | Quick Fast |

| Precision: | Accuracy |

| Maintenance: | Low Cost |

Shanghai Raylaser Enclosed Pallet Changer Series: Uninterrupted Production for Demanding Workshops

Experience continuous laser cutting operations with Shanghai Raylaser’s Fully Enclosed Pallet Changer Systems – engineered for high-volume production in the USA, Saudi Arabia, and global industrial hubs. Our enclosed table laser cutters combine robust fiber laser technology (1kW-60kW) with automated material handling, maximizing uptime while ensuring operator safety and precision cutting of steel, aluminum, and reflective metals.

Key Features & Technical Advantages:

Seamless Production Workflow

Dual-pallet system enables continuous 24/7 operation

Automatic loading/unloading reduces manual handling by 70%

Integrated safety interlocks (CE/OSHA compliant)

Industrial-Grade Enclosure

Full laser containment with 5mm steel panels

IP54-rated dust/particle protection for desert environments

Acoustic dampening (<75 dB noise output)

High-Precision Cutting Core

±0.03mm positioning accuracy with linear guides

120m/min maximum cutting speed (1.5G acceleration)

Auto-focusing Precitec/Raytools cutting heads

Smart Control Ecosystem

One-touch pallet cycling via 15" touchscreen HMI

Remote monitoring via Raylaser IoT platform

Collision avoidance sensors

Technical Specifications (Enclosed Series):

| Model | Cutting Area | Pallet Size | Exchange Time | Max Load | Laser Power |

|---|---|---|---|---|---|

| EPC-3015 | 3000x1500mm | 3100x1600mm | 18 sec | 3.5T | 1-20kW |

| EPC-4020 | 4000x2000mm | 4100x2100mm | 22 sec | 4.5T | 6-30kW |

| EPC-6020 | 6000x2000mm | 6100x2100mm | 25 sec | 6T | 15-60kW |

Standard Config: MAX/Raycus laser source • S&G chiller • 380V/3-phase power

Hermetic enclosure protects optics from sand/sediment (critical for Middle East operations)

Labor Cost Reduction

One operator manages multiple machines with automated material flow

Safety Compliance

Meets OSHA 1910 and Saudi SASO-ISO 12100 standards

Energy Efficiency

30% lower power consumption vs. traditional CO₂ systems

Plug-and-Play Installation

Pre-assembled modules with laser-aligned pallet rails

FAQs: Enclosed Pallet Changer Systems

Q: How does enclosed design improve safety vs open machines?

A: Full containment eliminates stray radiation risks while

containing metal fumes – essential for OSHA-compliant US workshops

and Saudi factories with strict HSE requirements.

Q: What maintenance does the pallet system require?

A: Our automated greasing system requires only quarterly servicing.

We provide lifetime-replaceable roller bearings and low-cost OEM

spare parts.

Q: Can I retrofit existing Raylaser machines?

A: Yes! TF-Edge open machines can be upgraded with EPC enclosures

in 3 days. Ask about our Saudi/USA retrofit programs.

Q: How does pallet changing impact productivity?

A: Reduce non-cutting time by 45%:

Typical manual changeover: 8-12 minutes

EPC automated change: 18-25 seconds

Q: What shipping protection do you provide?

A: Triple-layer protection:

Waterproof sealed enclosure

CNC-machined transport brackets

Real-time GPS-tracked containers

Global Support Infrastructure

With 16+ years in fiber laser manufacturing, Shanghai Raylaser

maintains:

USA: Spare parts warehouses in Houston/Chicago

Saudi Arabia: Technical center in Dammam

24/7 multilingual support (English/Arabic)

Door-to-door installation technicians

Why Industry Leaders Choose Raylaser:

*"Our Texas facility runs 3 EPC-6020 systems with 60kW lasers. We achieved ROI in 14 months through 24/7 stainless steel cutting with zero operator exposure."*

– Manufacturing Director, Aerospace Components Inc. (Houston)

|

Quality Cutting Thickness 0-30mm Enclosed Laser Cutting Machine with Exchangeable wholesale

Quality Cutting Thickness 0-30mm Enclosed Laser Cutting Machine with Exchangeable wholesale

Quality CNC Enclosed Laser Cutting Machine with MAX Raycus Laser Source fiber laser machine cnc metal cutting laser machine wholesale

Quality CNC Enclosed Laser Cutting Machine with MAX Raycus Laser Source fiber laser machine cnc metal cutting laser machine wholesale

Quality Flagship Metal sheet enclosed laser Cutting Machine stainless steel laser cutting machine 12 kw laser cutting machine wholesale

Quality Flagship Metal sheet enclosed laser Cutting Machine stainless steel laser cutting machine 12 kw laser cutting machine wholesale